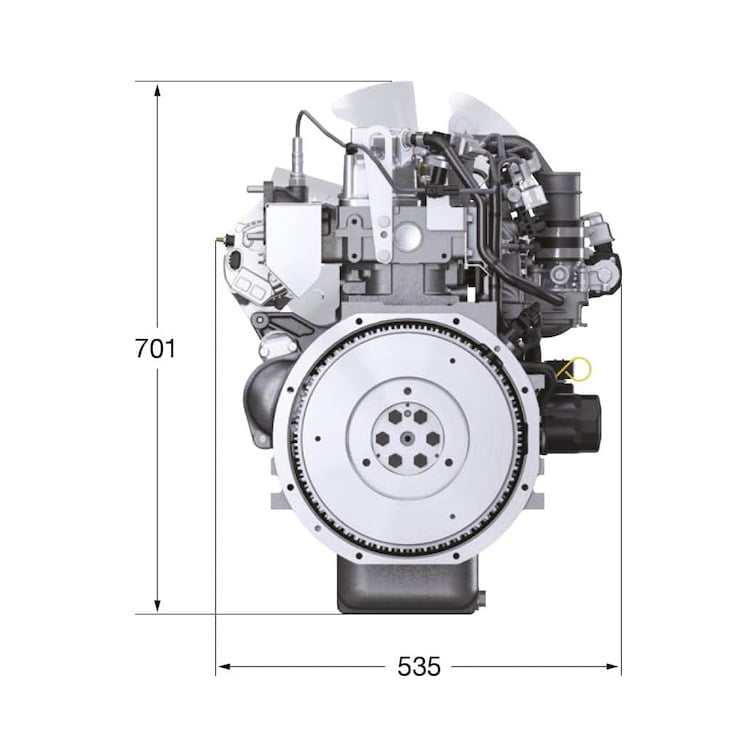

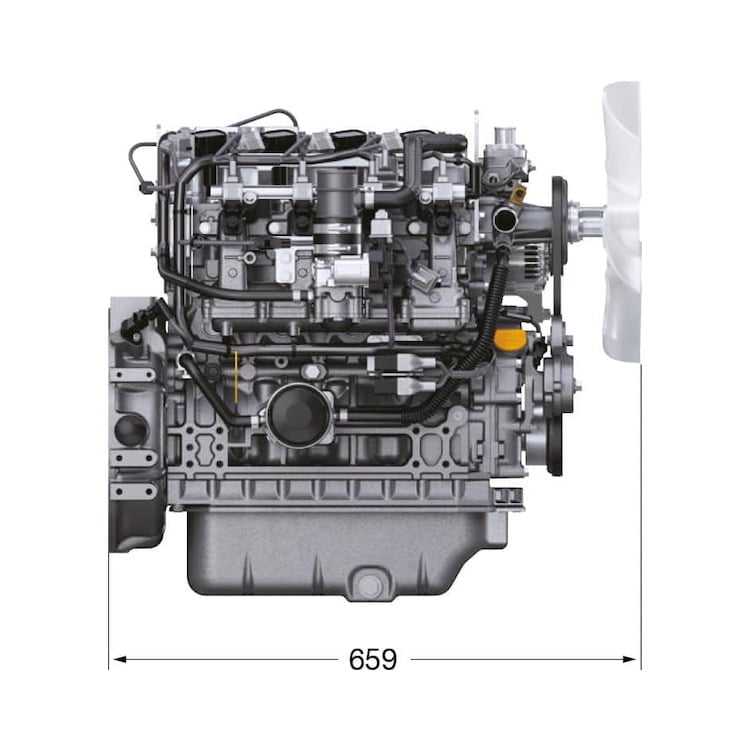

4TN88G

Vertical cylinder, 4-cycle water-cooled gas engine

View Specs- Maximum Power

- 45.0 kW

- Emission Industrial

- EU Stage V

- Warranty

- 5 Year Warranty

Product Specifications

- Fuel Type

- Gas

- Equipment Type

- Variable Speed Engines

- Maximum Output

- 45.0 kW / 2600 rpm

- Emission Industrial

- EU Stage V

- Displacement

- 2.190 ltr

- No. of cylinders

- 4 cylinders

- Aspiration

- Natural

- Bore x Stroke

- 88 mm x 90 mm

- Warranty

- 5 Year Warranty